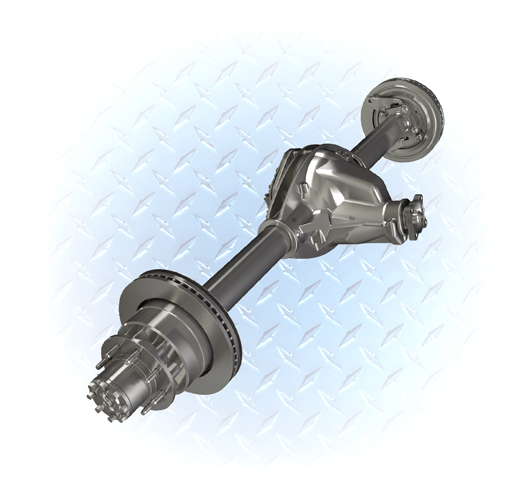

We engineer and manufacture a complete line of manual, semi-automatic, and fully automatic precision measurement and testing equipment for all axle-related assemblies and components

We engineer and manufacture a complete line of manual, semi-automatic, and fully automatic precision measurement and testing equipment for all axle-related assemblies and components.

Traditional equipment types for this application include balancing equipment, dimensional gages, NVH equipment (noise, vibration, and harshness), and functional test stands, as well as specialized test systems (including torque to turn, end play, backlash, and destructive torque testers).

Equipment layouts vary to accommodate any production rate. Typical correction methods for balancing include projection, spot welding (with automatic weight feed, form, and place), drilling, and milling. Typical NVH equipment includes both speed and torque sweep capability for complete data analysis.

Additionally, BTI’s unique ability to combine the aforementioned technologies into one fully integrated system enables our clients to reduce capital expenditures, increase product quality, and minimize floor space requirements.

Let our staff of more than 50 engineers design a custom solution for your specific requirements. Furthermore, our commercial Measurement & Testing Services Group (M&T Services) can assist with everything from prototype testing and R&D work to master certification and running small-to-medium production runs.

If you don’t see the product you are looking for, or have specific questions, please contact us.