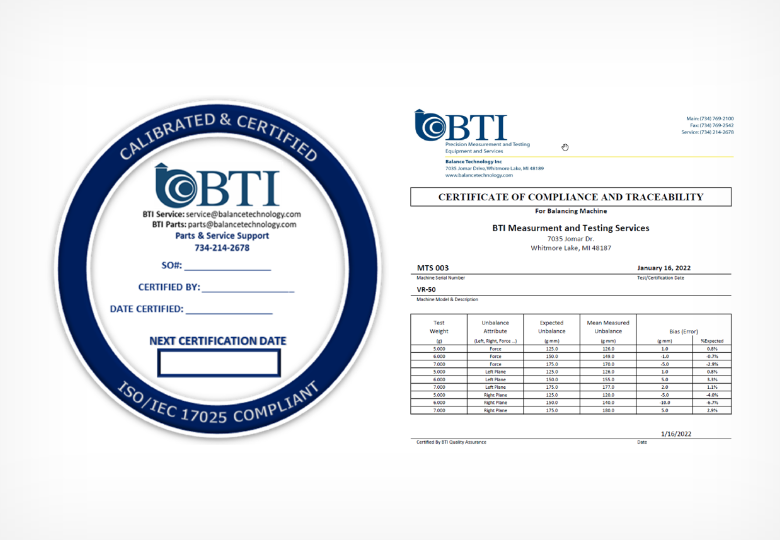

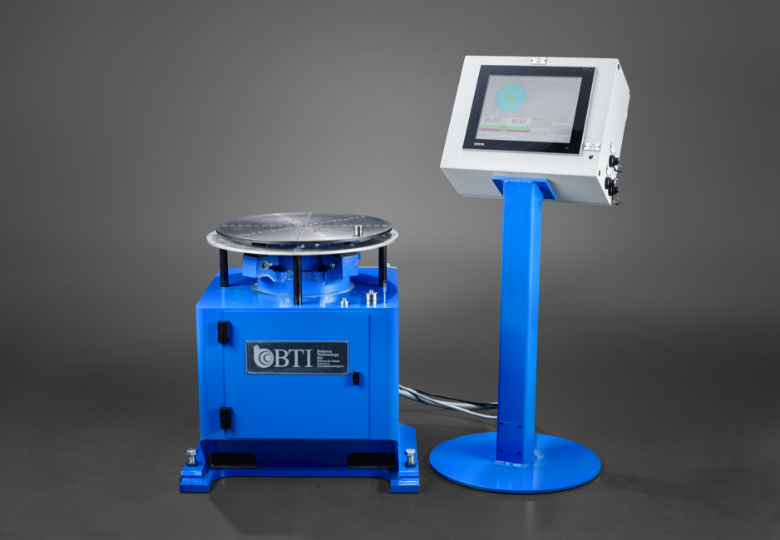

machine certification and calibration

Machine certification and calibration is a critical aspect of your product quality assurance. Our expert team focuses on calculating the measurement bias associated with the gauge, going beyond standard techniques.

This process ensures not only the precision and consistency of your machinery but also fosters trust in your product quality. With BTI’s services, you invest in accuracy and efficiency, enhancing your brand’s reputation for excellence.