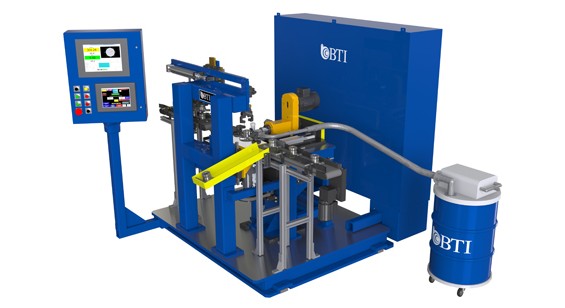

BTI engineers and manufactures a complete line of manual, semi-automatic, and fully automatic industrial dimensional gages for all part types and sizes.

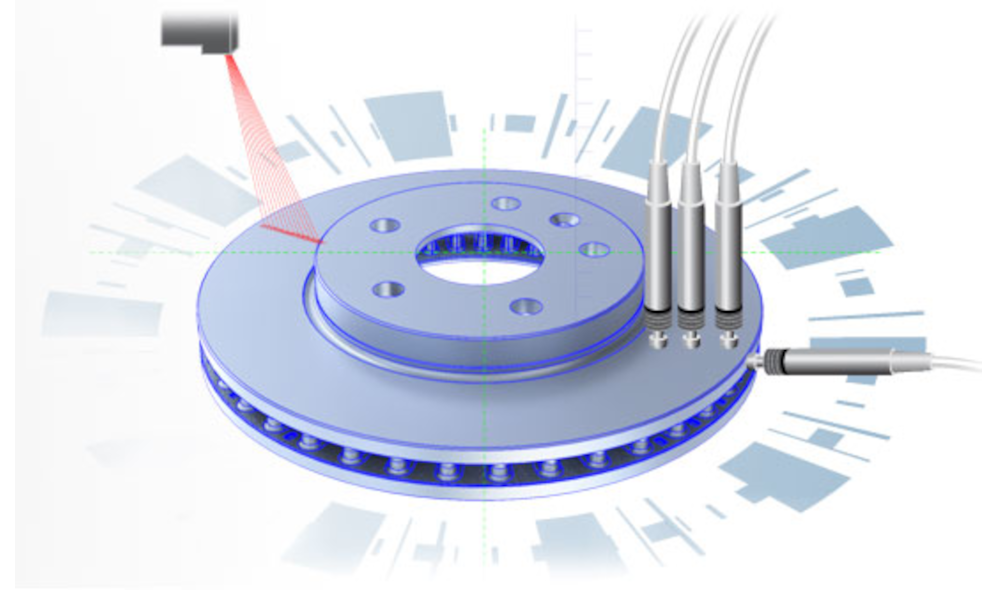

Our gages can handle all production rates and levels of automation, from contact-type LVDT probes to non-contact laser heads, static and dynamic measurements, and gaging under load. Whether it’s a single-station gage or a multi-station gage, BTI excels at all. Typical gaging attributes include:

Flatness

Straightness

Circularity

Cylindricity

Perpendicularity

Angularity

Parallelism

Profile of a Surface

Circular Runout

Total Runout

Concentricity

Symmetry

In addition to Dimensional Gages, BTI also engineers and manufactures other types of industrial precision measurement and testing equipment, including Balancers, mass centering equipment, eddy current crack detection systems, surface finish measurement equipment, NVH equipment (noise vibration and harshness), functional test stands, spinners, motor testers, and resonant frequency measurement systems.

We also engineer and manufacture specialized test systems, including torque-to-turn, backlash, end play, and destructive test equipment.

Additionally, BTI’s unique ability to combine the aforementioned technologies into one fully integrated system enables our clients to reduce capital expenditures, increase product quality, and minimize floor space requirements. There is no need for costly conveyors and escapements to connect independent machines together; nor do you need to train operators on multiple machines. There is one seamless, easy-to-use operator interface with unprecedented networking, statistical, and diagnostic capability.

Whether you need a fully integrated, combined technology system (e.g., a balancer/gage/NVH combo) or independent machines, let our team of mechanical, electrical, and software engineers design and build a custom system for you.

If you don’t see the product you are looking for, or have specific questions, please contact us.