No matter the brand, BTI will replace your existing computer with a new, industrial BTI computer

No matter the brand, BTI will replace your existing computer with a new, industrial BTI computer. Basic and complex solutions are available for onsite install or at BTI’s state-of-the-art manufacturing facility.

BTI utilizes industrial computers housed in NEMA 12-rated enclosures for use in harsh manufacturing environments. Our PCs feature many commercially available cards and components to provide high quality, exceptional reliability, and lower maintenance costs to our customers. Solid state drives (SSDs) are used to provide unparalleled system robustness, low power consumption, rapid start-up speeds, and increased reliability and uptime. Our PCs utilize a Microsoft Windows-based operating system for familiarity and ease of use.

In addition, we offer PLC upgrades. BTI has extensive experience in delivering advanced control software to meet the most demanding applications and specifications. We have programmed all major PLC brands, including (but not limited to) Rockwell Automation/Allen-Bradley, Siemens, Modicon, and Mitsubishi. BTI will implement your unique specifications and controls requirements with strong technical skill and programing excellence. Backed Up for Life: PC and PLC

Recognizing uptime is import, BTI creates a complete PC-system image of your computer prior to shipment. This image is saved and backed up on BTI’s secure server for the life of the machine. The backup software is installed on your PC so that BTI service or plant personnel can perform a backup at any time. In addition, the PLC logic is also backed up prior to shipment, and it too is saved and backed up on BTI’s secure server for the life of the machine.

See Rebuilds and Retrofits for additional upgrade services.

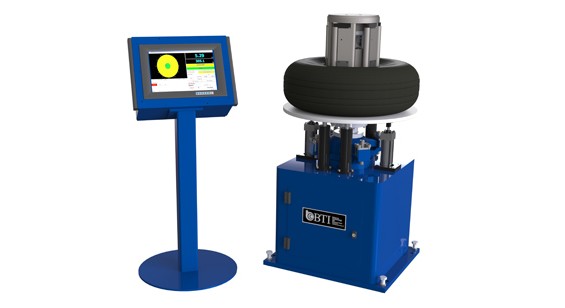

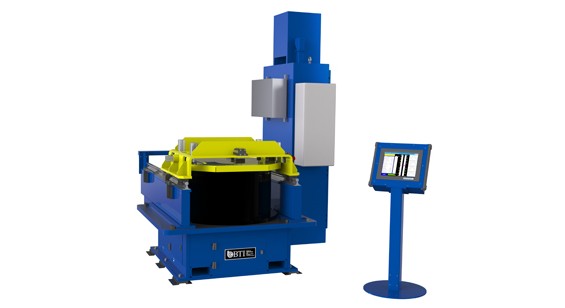

BTI also provides new equipment. We engineer and manufacture other types of industrial precision measurement and testing equipment, including static and dynamic balancing equipment, dimensional gages, mass centering equipment, eddy current crack detection systems, surface finish measurement equipment, NVH equipment (noise vibration and harshness), functional test stands, spinners, motor testers, and resonant frequency measurement systems.

We also engineer and manufacture specialized test systems, including torque-to-turn, backlash, end play, and destructive test equipment.

Additionally, BTI’s unique ability to combine the aforementioned technologies into one fully integrated system enables our clients to reduce capital expenditures, increase product quality, and minimize floor space requirements. There is no need for costly conveyors and escapements to connect independent machines together; nor do you need to train operators on multiple machines. There is one seamless, easy-to-use operator interface with unprecedented networking, statistical, and diagnostic capability.

Whether you need a fully integrated, combined technology system (e.g., a balancer/gage/NVH combo) or independent machines, let our team of mechanical, electrical, and software engineers design and build a custom system for you.

If you don’t see the product you are looking for, or have specific questions, please contact us.